With material selection and sourcing finalized, step two begins with foundational site visits and an in-depth assessment of the product’s purpose. This phase is dedicated to understanding the real-world challenges of customers and value-chain requirements, enabling us to pinpoint how the new or improved product can solve specific problems and create impact.

- Site Visits and Assessment of needs

AION starts by engaging directly with the client environment, immersing in the context to uncover the core needs and pain points. Whether observing existing processes, storage conditions, or distribution methods, this initial investigation reveals critical design considerations that help shape the vision for the product. These insights become the groundwork for addressing client-specific demands, from durability needs to cost-effective, sustainable materials.

distribution methods, this initial investigation reveals critical design considerations that help shape the vision for the product. These insights become the groundwork for addressing client-specific demands, from durability needs to cost-effective, sustainable materials.

- Brainstorming Solutions

With an understanding of the client’s operations, the design team conducts brainstorming sessions to generate targeted solutions. We focus on how the product will function, the primary challenges it will address, and where it can create value. If the design involves substantial innovation, these sessions are essential to explore different configurations, interactions, and features that respond to both user requirements and environmental factors.

- Visualizing and Developing the Concept

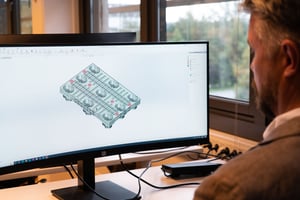

After defining the product’s purpose, we move into creating initial sketches and 3D models. These visuals help us present ideas to clients and stakeholders, facilitating feedback and refinement before moving to prototyping. For complex requirements, iterative modeling enables flexibility and adaptability, allowing us to test and adjust the design as needed for optimal performance.

- Eco-Friendly Design Optimization

Incorporating eco-design principles, we strive for minimalism, low component count, and ease of recyclability. Modular designs and adaptable elements are prioritized, allowing the product to not only fulfill its immediate purpose but also maintain long-term sustainability by integrating end-of-life recovery.

This approach to concept development and eco-friendly design optimization not only brings the product to life but ensures it aligns with both customer needs and sustainable design goals.

- Recyclability and End-of-Life Consideration

Recyclability is at the core of this phase, as end-of-life planning is integrated into the design. We aim to maximize a product's lifecycle and ensure that its components can be reused or recycled at end-of-life in an economical way. For instance, products that don’t require manual disassembly for recycling, made without reinforcements are more economical to recycle and keep in closed-loop systems, allowing materials to re-enter the value chain without generating waste.

- Design Optimization for existing products

For clients with existing products or designs ready for production, AION provides valuable input on design optimization and material enhancements. We assess current designs to identify opportunities for improvement in functionality, durability, and sustainability. Our expertise in recycled plastics ensures that clients can enhance their products while maintaining alignment with eco-friendly standards and regulatory requirements.

This collaborative process allows us to refine the product, ensuring it meets both performance expectations and environmental goals.

This approach to concept development and eco-friendly design optimization not only brings the product to life but ensures it aligns with both customer needs and sustainable design goals.