CIRCULAR INSIGHTS HUB

WELCOME TO AION'S CIRCULAR INSIGHTS HUB!

AION's circular insights hub is our collection of resources, all related to the circular economy and sustainable practices around plastics.

KEY TOPICS YOU'LL FIND ON THIS PAGE

The global plastic crisis has reached a critical point, necessitating urgent and innovative solutions. Learn about the circular economy and its impact on sustainability. Discover how AION is leading the shift to sustainable plastics through innovative solutions, creating positive environmental and financial impact for businesses.

.jpg?width=300&name=51702615886_66805aaf04_o%20(2).jpg)

.jpg?width=300&name=IMG_1877%20(3).jpg)

%20(1).png?width=300&name=image-removebg-preview%20(4)%20(1).png)

1. What is the Circular Economy?

Circularity is a term often used for sustainable consumption. Circularity seeks to: minimize the use of resources and raw material, reuse products to their maximum capacity and recycle them when they cannot be reused. It would also include to manufacture products considering their end-of-life and making sure that they end-up back in the supply chain.

The concept of Circularity is inspired by nature where the word “waste” does not exist, and everything has a purpose. In the natural ecosystem, everything is destined to renew itself. Everything has a lifetime where it serves its purpose and when the purpose is served, it either decomposes or changes its form into elements or compounds through different processes that are then reused to produce the same or a different structure. This circularity in the natural ecosystem helps to sustain an equilibrium that keeps everything going autonomously.

On the contrary, the linear economy (vs. the circular) production system by humans is based on a take-make-waste scheme, focusing only on the production and brief use of the product.

In the linear economy, waste management is usually ignored as a part of the product’s lifecycle. This unlimited extraction of resources, irresponsible production practices and unmanaged waste generation is causing unbearable burden to the earth’s ecosystems, disturbing the natural balance which is heavily impacting the entire planet including humanity.

Humans have generated so much waste that it can take an eternity to reverse the impact. In order to keep the same or better standards of living, the only way forward is to integrate rules of circular economy in production and consumption, choosing options that are renewable and acting responsibly.

In short, Circularity focuses on the “reduce-reuse-recycle” strategy to minimize waste, emissions and resource depletion. This can be done by manufacturing products in a responsible way so the material can be used multiple times, minimizing the long-term impact on our environment, health and prosperity.

At its core, the circular economy seeks to keep products, materials, and resources in use for as long as possible, minimizing waste and maximizing value. This approach is particularly critical in addressing the global plastic crisis, which poses a significant threat to our ecosystems and natural resources.

More insights on Circular Economy topics:

- Understanding the Circular Economy: Explore the core principles of the circular economy and its potential to drive sustainable development. Learn how the circular economy approach differs from the linear economy and its benefits for businesses, the environment, and society.

- The Importance of Sustainability: Understand the growing significance of sustainability in modern business practices. Discover how companies can integrate sustainable practices into their operations and reap the associated benefits.

- The Role of Plastics in a Sustainable Future: Examine the environmental impact of plastics and explore sustainable solutions for their production, use, and disposal. Learn about the role of innovation and regulation in promoting a more sustainable plastics economy.

2. What are the benefits of Circulairty?

1. Less waste, less pollution

When we design products to be reused, repaired, or recycled, we create way less trash. That means fewer landfills and less plastic polluting our oceans.

2. Environmental protection and resource optimization

By using recycled materials and keeping products in use longer, we cut back on the need for virgin resources like oil, metals, and wood , helping to protect the planet’s natural reserves.

3. Lower carbon emissions

With less need to extract raw materials, manufacture new products, and manage waste, we can also achieve a significant reduction in greenhouse gas emissions

4. Drives innovation

A circular economy challenges companies to rethink how things are made. This leads to smarter, more sustainable designs and supply chains that help businesses stand out.

5. Creates new jobs and industries

More focus on repair, remanufacturing, and recycling means new industries emerge, and with them new job opportunities are created.

6. Stronger, more resilient supply chains

By relying on recycled materials and local resources, companies become less vulnerable to raw material shortages and price spikes.

THE TRANSITION FROM LINEAR TO CIRCULAR SYSTEMS

Solving the plastic waste crisis: Transitioning from a linear to a circular economy involves a holistic approach that need to rethink the entire lifecycle of plastics.

3. How to succeed with Circular Design

Designing for circularity is a critical step towards a more sustainable future. By understanding the properties of different plastics and adhering to key design principles, manufacturers can create products that are easier to recycle and less harmful to the environment.

- 01 Material selection

- 02 Design for reuse and repairs

- 03 Effective recycling

The first step in designing for recyclability is understanding the different types of plastics. At AION we prefer using recycled plastics from a known or certified source. Common plastics include:

- Polyethylene Terephthalate (PET): Often used in beverage bottles, food containers and hard transparent packaging.

- High-Density Polyethylene (HDPE): Detergent bottles, toys, dustbins and rotomolded boats.

- Low-Density Polyethylene (LDPE): Used in plastic bags, six-pack rings, and various containers.

- Polypropylene (PP): Common in automotive parts, textiles, and reusable containers.

- Polystyrene (PS): Used in disposable coffee cups, single use cutlery.

Each type of plastic has unique properties and recycling processes, so it's essential to choose the right material for the intended application, keeping in mind the products end-of -life

Single-use and short lived products have little room in the circular economy. Reusing products reduces waste, pollution and GHG emissions and is key to enabling circularity.

Designing products in high-quality materials, with plans for sustainable and effective labeling, fit for disassembly and with as little complexity as possible ensures more reuses, and easier and cheaper repairs - extending product life even further.

Check out some more on circular products

Once the product reaches it's end-of-life, material selection and product design will heavily impact if your product can be recycled into new material, and how much this process will cost. Opting for recyclable plastics without contaminants or labels that will ruin material quality - results in easy to recycle products and cheaper materials that support a circular loop for your products.

Resource recovery is a critical component of the circular economy, focusing on the efficient collection, processing, and re-utilization of materials from end-of-life products. Instead of allowing valuable materials to end up in landfills or incinerators, resource recovery aims to reclaim these materials and reintroduce them into the production cycle, thus closing the loop.

4. Why is traceability the key to Circularity?

The role of traceability in a circular economy

Traceability is the ability to track materials through the entire value chain. and is essential to achieving a truly circular economy. It allows manufacturers, regulators, and consumers to follow the lifecycle of plastic, ensuring transparency in sourcing, usage, and recycling.

While traceability is already a well-established concept in manufacturing for compliance and quality control, it is often lost once a product reaches the end of its initial use. This lack of oversight creates a major barrier to circularity, as the absence of information about a material’s history makes it difficult to recycle effectively and limits its potential for high-value reuse.

The challenge of recycled plastics: Quality and variability

Unlike virgin plastics, which have known and consistent properties, recycled plastics can vary significantly in quality depending on their previous use, exposure to environmental factors, and how they were collected and processed.

Without traceability, manufacturers are often left with uncertainty about the composition and performance of the recycled material they receive, leading to inefficiencies and additional costs in production.

By implementing robust traceability systems, companies can gain better control over their recycled plastic feedstock. This means knowing where the plastic has been used before, how it has been treated, and whether it contains additives or contaminants that may impact its quality. When manufacturers have this information, they can make more informed decisions, optimize processing conditions, and ensure higher-quality output, ultimately increasing trust in recycled materials as a viable alternative to virgin plastics.

Preventing down-cycling: The role of traceable value chains

One of the biggest risks to achieve true plastic circularity is downcycling, the process where plastic is repeatedly recycled into lower-value applications until it eventually becomes waste. This often happens because mixed or poorly documented plastic streams lack the necessary quality controls to be used in high-value applications.

When plastic is recycled without a traceable value chain, it is typically blended with other unknown sources, resulting in unpredictable material properties. Over time, this leads to lower-performance plastics that can only be used for applications like low-grade packaging or composite materials, rather than being turned back into high-quality products. By contrast, maintaining strict traceability allows companies to retain the integrity of materials, ensuring that plastics can be reused at their highest potential rather than being permanently downgraded.

Mass balance and transparency in reporting

Mass balance methodologies play a crucial role in enabling traceability for recycled plastics. These systems track the input and output of recycled material through the supply chain, ensuring that the amount of recycled content claimed in a product matches the actual material used. Accurate reporting and certification of mass balance provide transparency, helping both regulators and businesses validate sustainability claims and avoid greenwashing.

For industries reliant on plastics, a shift toward verified traceability systems can drive meaningful progress toward circularity. Digital tools and tracking solutions are increasingly being used to enhance visibility across supply chains. Such technologies ensure that materials retain their highest possible value while improving compliance with evolving sustainability regulations.

5. Navigating EU Regulations on Plastics

The European Union is driving a major shift in how plastics are produced, used, and recycled through an evolving regulatory framework. At the heart of this transformation is the European Green Deal, which aims to reduce plastic waste, increase recycling, and promote sustainable material use across industries.

Key policies such as the Single-Use Plastics Directive (SUPD), the Packaging and Packaging Waste Regulation (PPWR), and the Corporate Sustainability Reporting Directive (CSRD) are shaping the future of plastic consumption and waste management.

The bigger picture

These regulations present both challenges and opportunities for businesses. While compliance requires significant adjustments, they also drive innovation in sustainable materials, circular business models, and improved recycling systems. Companies that invest in traceability, high-quality recycled materials, and sustainable product design will be well-positioned to navigate the regulatory landscape and lead the transition to a circular economy.

Key regulatory developments

-

Mandatory Recycled Content: EU legislation is setting minimum recycled content requirements for plastic packaging, ensuring a reduced dependency on virgin fossil-based plastics.

-

Plastic Reduction Targets: Countries must cut plastic packaging waste by 5% by 2030, 10% by 2035, and 15% by 2040, pushing industries toward reusable and recyclable alternatives.

-

Extended Producer Responsibility (EPR): Companies are held accountable for the entire lifecycle of their plastic products, including collection, recycling, and disposal costs.

-

Ban on Single-Use Plastics: Several categories of single-use plastic packaging are being phased out, with increasing restrictions on non-recyclable designs.

-

Plastic Taxes and Fees: Additional costs are imposed on non-recyclable and fossil-based plastic products, incentivizing circular solutions.

-

Digital Product Passports (DPP): By 2030, many plastic products will require detailed traceability information to improve transparency and recyclability.

6. Strategies for plastic waste

Despite advancements in recycling technology, the majority of plastic waste globally still ends up in landfills. This represents a massive loss of valuable materials and contributes to environmental pollution. A shift towards better sorting, improved waste streams, and scalable recycling solutions can provide economic and environmental benefits by transforming plastic waste into high-quality raw materials.

Mechanical Recycling:

Mechanical recycling is the most widely used and established method for plastic waste management. This process involves collecting, sorting, washing, shredding, and remelting plastics to create new products.

- Lower energy consumption compared to other recycling methods.

- Maintains the material properties when high-quality sorting is implemented.

- Cost-effective at scale, providing a lower-cost alternative to virgin plastics.

- Quality degradation over multiple recycling cycles.

- Contamination from additives, colors, and mixed plastic types.

- Limited applicability for complex plastic structures and multilayer packaging.

Chemical Recycling:

Chemical recycling breaks down plastics into their molecular components, enabling the production of high-quality recycled materials that can be used for a broader range of applications.

- Can process mixed and contaminated plastics that are unsuitable for mechanical recycling.

- Produces high-quality feedstock similar to virgin plastic.

- Offers the potential for infinite recycling cycles without material degradation.

- High energy and infrastructure costs.

- Limited commercial scalability compared to mechanical recycling.

- Some processes still rely on fossil fuel-based inputs to drive the chemical reactions.

Incineration (energy recovery):

Incineration, or energy recycling, involves burning plastic waste to generate electricity or heat. While this process reduces landfill volume, it is often criticized for its environmental impact.

- Reduces waste volume and prevents landfill overflow.

- Generates energy that can be used for heating and electricity.

- Effective for non-recyclable and contaminated plastics.

- Releases CO2 and other pollutants unless combined with carbon capture technology.

- Inefficient compared to reusing plastics in a circular system.

- Does not contribute to material recovery and circularity.

Scaling solutions

To achieve better economic and environmental returns, plastic waste strategies must focus on optimizing sorting, collection, and processing. High-quality granulate from recycled plastics can be produced at a lower cost than buying off-the-shelf recycled materials—and potentially even cheaper than virgin plastic if scaled efficiently. However, success ultimately depends on:

Advanced sorting technologies to improve material purity.

Infrastructure investments in both mechanical and chemical recycling facilities.

Regulatory support to incentivize recycling over landfill and incineration.

Industry collaboration to create closed-loop systems that retain material value.

By prioritizing scalable recycling solutions, industries can reduce reliance on virgin plastics, minimize environmental impact, and contribute to a more sustainable future.

7. Other insights and articles

Bioplastics sounds like an appealing solution to the plastic crisis - but what is actually bioplastics?

READ MORE ABOUT THIS EVENT

As a cost-efficient solution for companies to meet EU Regulations on plastic

READ MORE ABOUT THIS EVENT

Dive into new and upcoming EU regulations facing manufacturer and users of plastic products.

READ MORE ABOUT THIS EVENT

Circular products are at the heart of the circular economy, designed with sustainability, longevity, and recyclability in mind

READ MORE ABOUT THIS EVENT

Sustainability is a crucial aspect of modern business practices, driven by the growing recognition of the need to balance economic growth with environmental responsibility.

Read More

We believe that any business should reconsider their business model if they (1) are depending on global value chains, (2) need scarce and non-renewable materials and where (3) the material cost is a significant part of the product price

Read More

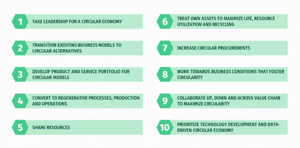

Skift, WWF, SINTEF and Deloitte have launched 10 principles for a circular economy. The principles are guides and examples that businesses can build on and implement to become more circular.

Read More

Dive into the importance of these directives for businesses operating in the logistics sector. Especially reuse and recycled content targets can be challenging to meet for transport packaging

Read More

AION discusses how businesses play a cruicial role in the transition to a circular economy with Lars Pedersen and Sveinung Jørgensen who head the Centre for Sustainable Business at the Norwegian School of Economics.

Read More