AION SERVICES

DOES YOUR COMPANY HAVE A PRODUCT OR AN IDEA YOU WANT TO PUT TO LIFE?

With in-house design expertise, we create durable, eco-friendly products for various industries, focusing on material selection, efficient manufacturing, and recyclability. Whether you need support from the early concept phase or are ready to optimize and produce an existing product, we ensure innovative solutions tailored to environmental and market demands.

The key steps in this process are:

ALREADY HAVE A FINISHED DESIGN OR PRODUCT YOU WANT AION TO HELP YOU WITH?

AION offers tailored solutions to address your specific needs, even if this is only manufacturing, sourcing of recycled materials or other1. Concept & Development

We start by deeply understanding our customers needs, assessing their challenges, and brainstorming solutions that align with their goals. We ensure innovative ideas that are sustainable and user-centric, setting a solid foundation for successful design. Site visits and evaluation of similar products can both be a key step in this process.

AION can assist in developing everything from complex industrial products to simple designs.

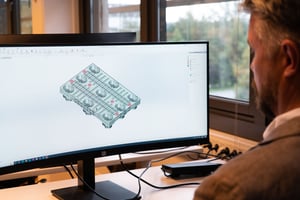

2. Design & Prototyping

Our inhouse experts have significant experience from designing products fit for automation, manufacturing (DFM) and an efficient value-chain, and uses tools like SolidWorks. We create precise 3D models and draft detailed design concepts. AION will produce designs fit for the selected manufacturing process. Our prototyping capabilities include:

- 3D Printing for rapid, cost-effective prototypes.

- Machined Prototypes for high-precision parts and testing.

- Custom Molding for specific form and function needs.

3. Material Sourcing

AION work with premium and traceable recycled plastics, ensuring high standards and stability in quality. As we utilize materials for our existing product portfolio, these are materials and value-chains we already in-depth knowledge on. Our standard materials include:

- HDPE (High-Density Polyethylene)

- PP (Polypropylene)

- LDPE (Low-Density Polyethylene)

These materials often come from marine industry waste such as nets, ropes, trawls, and big bags, supporting sustainability and resource efficiency. If you have other material needs or your own sources of plastic waste you'd like us to utilize then AION can evaluate this through our "Waste to Resource" solution.

4. Tools & Manufacturing

We guide clients on the best manufacturing processes tailored to their product, volume, and budget, ordering the correct tools needed for manufacturing. Processes we work with often are:

- Injection Molding for detailed and mass production.

- Extrusion for consistent, long pieces.

- Rotational Molding for hollow products.

- Blow Molding for items like containers.

- Vacuum Forming for blister type products

- Machining

If you have another manufacturing process in mind let us know and we'll be happy to evaluate if we're able to assist you.

5. Supply & Quality Assurance

After everything is set up, AION can take on the role as the single-point of contact in supply of products. Handling material and order processes. As well as delivering you with our annual Impact report on orders for that year.

Our robust quality assurance protocols are set up with manufacturing to ensure structural performance, quality, regulatory compliance and aesthetics are all upheld. This stage is crucial for confirming that your products meet durability and usability standards.

6. End-of-Life Solutions

Waste to Resource Solution for your Plastics

Interested in taking circularity one step further? Making a resource of the plastic used in your existing value-chains will have a real impact for your waste reduction goals, your GHG emissions and could have real financial benefits.

AION experts can analyze your materials and provide strategic advice on designing out waste from your value chain. With our wide network of suppliers we'll help you find the right recycling for your needs.

DATA COLLECTION

DATA COLLECTION

The first step is to collect as much information as we can on the type of plastics your company and value-chain have. Material composition, use, contaminations and volumes are key factors in evaluating if we can take your waste into recycling and use for our or your products.

SITE VISITS AND ASSESSMENT

SITE VISITS AND ASSESSMENT

AION experts are always happy to visit your site(s) to further collect the information we need to evaluate the value and the use of your plastic. This can also be done as a first step if you lack material knowledge on the plastics you'd like AION to investigate

"PROOF OF CONCEPT" PILOT

"PROOF OF CONCEPT" PILOT

Once the initial assessment is complete and AION knows what materials to move forward with. We will set up a proof-of-concept pilot to evaluate the quality of your recycled plastic. In the end we will assist in establishing an effective recycling processes.PARTNER WITH AION

Partner with AION to transform your waste challenges into opportunities for sustainability and innovation. Together, we can create a circular future where waste is minimized, resources are maximized, and environmental impact is reduced.CUSTOMER CASE STUDY